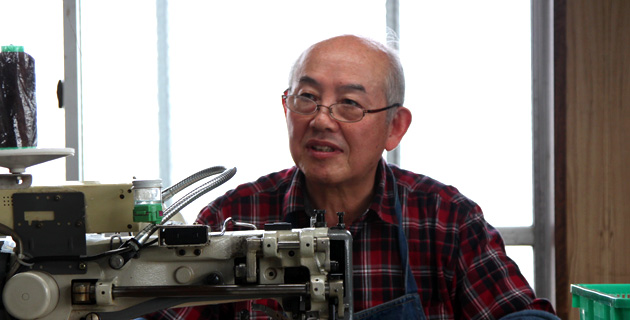

Interview : Bag maker Tadahiko Nakaune

Leather is a material that cannot be redone once it has been sewn.

JAPANTWO(JP2): Tell me about your thoughts on bag making.

Nakaune(N): Leather is a material that cannot be redone once it has been sewn, mistakes are not allowed. So, it requires a lot of concentration. I also endeavor to make bags faithfully following the designer's instructions about size and specifications.

Uematsu (YOSHIDA & CO., LTD. PR /U): Unlike cloths, holes that are made into leather will remain. The marks stand out even if you take out the stitches, so we won't be able to sell it as a product once a mistake has been made. That's why the process involves a lot of focusing.

N: Seasons have influence on conditions because leather tends to get soft during the summer and hard during the winter. Also, I pay close attention to not only the appearance but also to keeping the stitches the same and to making sure that the tags are sewn on straight. And when I sew small parts, I try to make smaller stitches. Large stitches look bad on small parts and labels, so I pay close attention to these details.

I always think about the pleasure for customers.

JP2: What is the hardest part of bag making?

N: Definitely the handling of the products. For example, leather gets scratches easily so I can never let it rub against the sewing machine table or anything. I am cautious on that point when I work with leather.

JP2: How are your feelings when making bags?

N: While making bags, I always think about the pleasure for customers. No matter how many bags I make, it means nothing if it doesn't make them happy. I also consider what images came into the designers mind when they designed the bags.

I don't think of it as too much work because there is a need for it.

JP2: Is there anything difficult when you make bags for Yoshida & Co., Ltd.? And how about Yoshida's quality consciousness?

N: Well, although it is not necessarily a matter of particular importance, I have a strong feeling for carefully sewing just as the company's motto "Heart and soul into every stitch". Yoshida & Co., Ltd. also very much do consider durability. For instance, after sewing the outer and inner materials together, they would ask us to bind nylon tape on the seams and sew over it again. In this way, I make sure the bags will not break apart, even if the thread goes loose somewhere. In fact, I am sewing four times for this bag that I am making right now. I also pay attention to how it should be sewn. If the needle go through the same spot too many times, it would just backfire, since it would put too much strain there and cause it to rip. So shifting the position of the stitches a little bit is the crucial point. Gradually shifting position of the stitches is one of the techniques I use, which can only be done on leather. For other materials like nylon, or polyester, I use a different technique. Like that, I select the way which suits each material.

JP2: What do you think about having to sew so many times?

N: I don't think of it as too much work because there is a need to do it. The designer put their thoughts into it, so I must not change that to make it easier. There is an important meaning to the fact that Yoshida & Co., Ltd. requested me to sew this part three times, where other bag makers usually sew twice. But then some bag makers who hope to finish faster reduces this process. It differs in that respect.

JP2: Will it become difficult to break if you add this process?

N: Sure. Well, even though the leather bag itself does not break, of course the metal parts of it like the zippers will wear down over time. However, Yoshida's products last a lot longer compared to others, and it is popular even amongst young people for that. The other day I saw an office worker with Yoshida's briefcase, and also my grandson has one. When I receive bags for repair, I can tell immediately whether or not a lot of work has been put into it or not. This is because if the bag wasn't sewn so many times, I'm able to break up the bags easily with little effort. But to tell you the truth from a bag maker's point of view, the bags made with cutting corners are so much easier to repair for us because there will be less work.

I really hope for more craftsmen in Japan.

JP2: Do you have any thoughts on "Made in Japan"?

N: There are many cases in which I feel that Japanese products are better. I think Japanese craftsmen have some similarities with German craftsmen in that we pay close attention to the details. Everything is made very neatly and carefully. For example, sewing machines that are made in Japan are much smoother in movement compared to those made elsewhere. I think there would be more craftsmen in Japan if we have a system like Germany in which skilled craftsmen are nationally licensed as a meister and have their works acknowledged to the public. I really hope for more craftsmen in Japan. Today, in downtown of Tokyo, there is an increase in many young people going to schools to learn crafts and engineering to start up a company, but I still wish Japanese craftsmen would increase in number more and more. Of course we need experienced craftsmen, but young people have new ways of thinking, so we definitely need young craftsmen as well. But, to be a craftsman, I think it is necessary to have an eye out for not only one, but all kinds of fields. For example, when watching a drama on TV, it is also important to look at the background at the same time, such as why that object is placed at that specific place in that teledrama. Just like a teledrama won't be as interesting without the background images, a craftsman must pay attention to the details and why there are such backgrounds, and be able to learn from such things. My feelings towards "Made in Japan " is not limited to just bag making, but it goes to all of Japan with the wish for more young Japanese to be involved in the manufacturing.

A Message for fans

JP2: To wrap it up, can you give a message to the current and future fans of Yoshida 's products that are abroad?

N: Yoshida's bags are very light, durable, and comfortable to use. I want everyone to actually use it and recognize the quality. Bags of luxury brands are of course very nice, but for everyday use, I recommend Yoshida's bags. In addition to that, I expect for new suggestions and ideas from consumers in foreign countries, and I think that such demands would lead to the creation of better bags. The way people abroad incorporate bags into their lives is not necessarily the same as in Japan. If we could work on that, I believe Yoshida & Co., Ltd. will spread even more into the world. So please, to those of you living abroad, try using a Yoshida's bag and experience it for yourselves.

Website http://www.yoshidakaban.com/